Izingxenye ze-Titanium alloy Ingxenye kagandaganda/Umshini Wesihlabathi Sensimbi/Insimbi Ewumshini /Izingxenye Zomshini/Izingxenye Zezimoto Zomzimba We-Compressor

| Okubalulekile | I-Aluminium: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Insimbi engagqwali: SS201, SS301, SS303, SS304, SS316, SS430 njll | |

| Insimbi: insimbi emnene / i-carbon steel kufaka phakathi i-1010, i-1020, i-1045, i-1050, i-Q690 njll. | |

| Ithusi: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 njll. | |

| Ithusi: C11000, C12000, C12000, C17200, C72900, C36000 njll. | |

| Iyacubungula | I-Germany Trumpf brand Laser cutter, umshini wokugunda we-CNC, umshini wokugoba we-CNC, |

| (CNC) umshini wokugxiviza, Umshini weHyraulic, Umshini wokushisela ohlukahlukene, CNC isikhungo somshini. | |

| Ubuso | I-Aluminium: I-anodization, i-Sandblast, i-Brushing, i-Polishing, i-Electro-plating njll |

| Insimbi Engagqwali: Ukupholisha, Ukuxubha, Ukudlula, I-Sandblasting, i-Electro-plating | |

| Insimbi: I-Zinc plating, i-Nickel plating, i-Chrome Plating, I-Powder Coating, Ukudweba njll. | |

| I-Brass & Copper: Ukuxubha, Ukupholisha njll | |

| Ukunemba | + - 0.1mm |

| Isicelo | Isitimela, Imoto, Iloli, Ezokwelapha, Imishini, Imishini, Ezogesi, Ezogesi njll |

I-Titanium wuhlobo olusha lwensimbi.Ukusebenza kwe-titanium kuhlobene nokuqukethwe kokungcola okufana nekhabhoni, i-nitrogen, i-hydrogen nomoya-mpilo.Okuqukethwe ukungcola ku-iodide ye-titanium emsulwa kungaphansi kuka-0.1%, kodwa amandla ayo aphansi futhi ipulasitiki iphezulu.Izakhiwo zika-99.5% ze-titanium ezihlanzekile zezimboni zimi kanje: ukuminyana ρ=4.5g/cm3, indawo encibilikayo 1725℃, ukuhanjiswa kwe-thermal λ=15.24W/(mK), amandla aqinile σb=539MPa, ubude δ=25%, ukuncipha kwesigaba ψ=25%, imodulus yokunwebeka E=1.078×105MPa, ubulukhuni HB195.

Amandla aphezulu

Ubuningi bengxubevange ye-titanium ngokuvamile buba ngu-4.51g/cm3, kuphela u-60% wensimbi, futhi amanye ama-alloy aqinile e-titanium adlula amandla ezinsimbi eziningi zesakhiwo sengxubevange.Ngakho-ke, amandla athile (amandla/ukuminyana) engxubevange ye-titanium makhulu kakhulu kunezinye izinto zesakhiwo sensimbi, ezingakhiqiza izingxenye ezinamandla amakhulu eyunithi, ukuqina okuhle nesisindo esincane.Izingxenye zenjini yendiza, uhlaka lwamathambo, isikhumba, izinsimbi kanye nemishini yokumisa konke kusebenzisa ingxubevange ye-titanium.

Amandla aphezulu okushisa

Izinga lokushisa lokusetshenziswa lingamakhulu ambalwa amadigri aphezulu kunengxubevange ye-aluminium, isengakwazi ukugcina amandla adingekayo ekushiseni okuphakathi, ingasebenza isikhathi eside ekushiseni okungama-450 ~ 500℃.Lezi zinhlobo ezimbili ze-titanium alloy ku-150℃ ~ 500℃ uhla zisenamandla athile aphezulu kakhulu, futhi ingxube ye-aluminium engu-150 ℃ amandla athile ehle kakhulu.Izinga lokushisa lokusebenza le-titanium alloy lingafinyelela ku-500℃, kuyilapho ele-aluminium ingxubevange lingaphansi. 200℃.

Ukumelana kahle nokugqwala

Ukumelana nokugqwala kwe-titanium alloy kungcono kakhulu kunokwensimbi engagqwali emkhathini omanzi namanzi olwandle.Ukugqwala kwe-pitting, ukugqwala kwe-asidi, ukumelana nokugqwala kwengcindezi kunamandla kakhulu;Inokumelana nokugqwala okuhle kakhulu kwe-alkali, i-chloride, imikhiqizo ye-chlorine ephilayo, i-nitric acid. , i-sulfuric acid, njll.Kodwa ukumelana nokugqwala kwe-titanium ekunciphiseni umoya-mpilo kanye ne-chromium medium kubi.

Ukusebenza okuhle kwezinga lokushisa eliphansi

Ingxubevange ye-Titanium ingakwazi ukugcina izakhiwo zayo zemishini emazingeni okushisa aphansi naphansi kakhulu.Ama-alloys e-Titanium anokusebenza okuhle kwezinga lokushisa eliphansi kanye nezakhi eziphansi kakhulu ze-interstitial, njenge-TA7, zingagcina ipulasitiki ethile ku--253℃.Ngakho-ke, i-titanium alloy nayo ibalulekile ebalulekile. izinga lokushisa eliphansi impahla yesakhiwo.

Ukusebenza kwamakhemikhali aphezulu

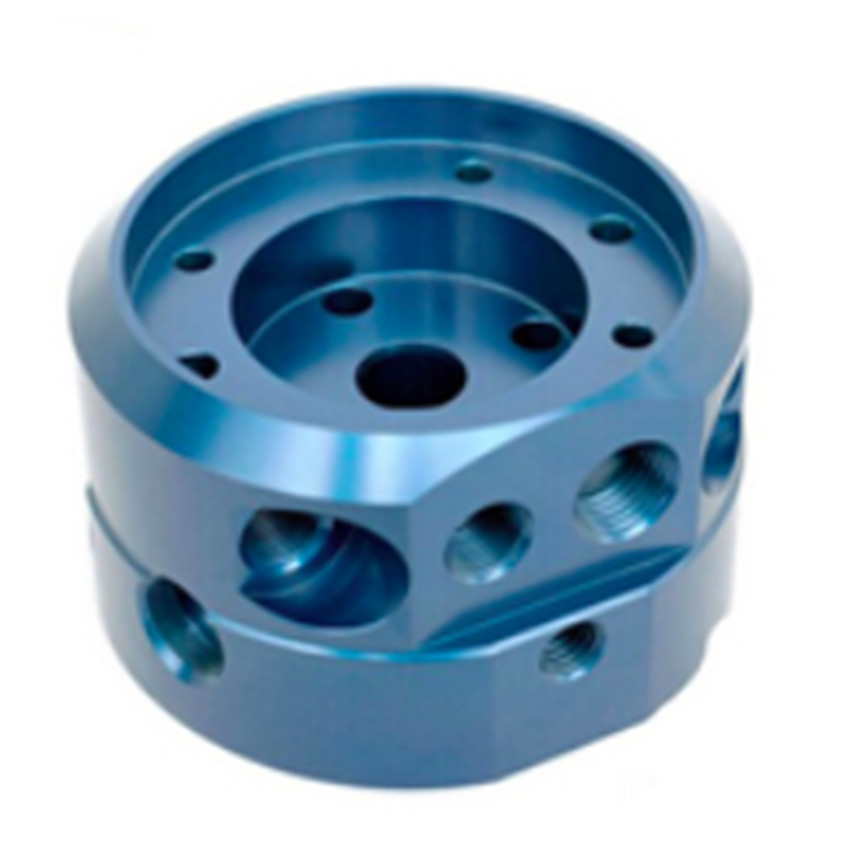

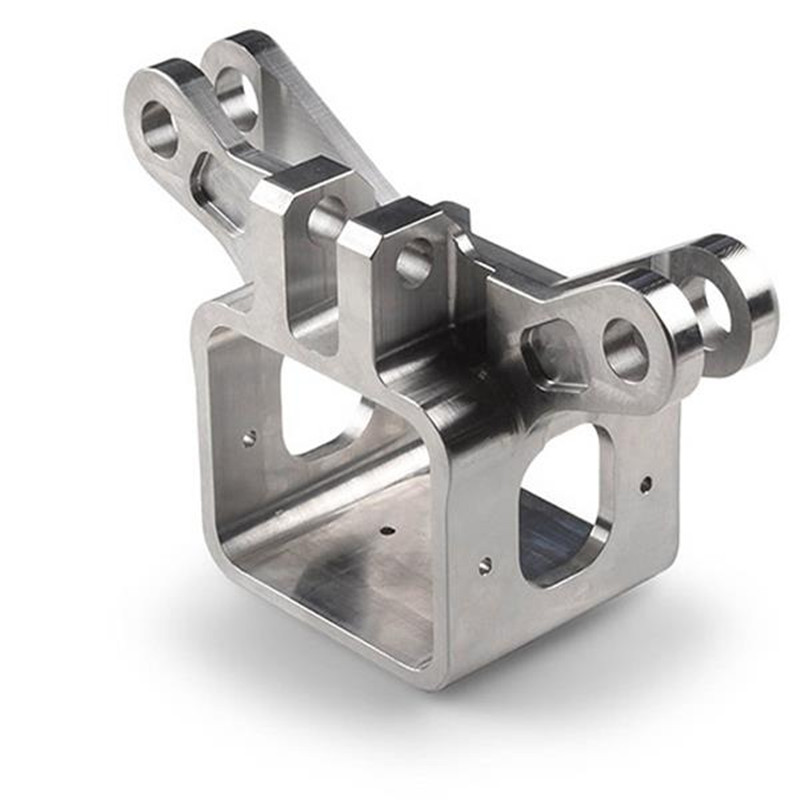

Imikhiqizo ye-Titanium alloy

Imikhiqizo ye-Titanium alloy

I-Titanium inokusabela okunamandla kwamakhemikhali ne-O2, N2, H2, CO, CO2, umhwamuko wamanzi, i-ammonia namanye amagesi emkhathini. izinga lokushisa liphezulu, ungqimba oluqinile lwe-TiN luzokwakhiwa ngokusebenzisana ne-N. Lapho izinga lokushisa lingaphezu kuka-600℃, i-titanium imunca umoya-mpilo futhi yakhe ungqimba oluqinile olunokuqina okuphezulu.Njengoba okuqukethwe kwe-hydrogen kuphakama, ungqimba oluphukayo luyoba Ukujula kongqimba oluqinile noluphukayo olukhiqizwa ukumuncwa kwegesi lungafinyelela ku-0.1 ~ 0.15 mm, kanti izinga lokuqina lingama-20% ~ 30%. phezulu.

Ukunwebeka kwe-thermal conductivity encane

I-thermal conductivity ye-titanium (λ=15.24W/(m·K)) cishe i-1/4 yaleyo ye-nickel, i-1/5 yensimbi, i-1/14 ye-aluminium, kanye nokusebenza okushisayo kwe-titanium ehlukahlukene. ama-alloys cishe aphansi ngo-50% kunalawo e-titanium.I-elastic modulus ye-titanium alloy cishe i-1/2 yensimbi, ngakho ukuqina kwayo akulungile, kulula ukuguquguquka, akufanele kwenziwe ngentonga emincane kanye nezingxenye ezinodonga oluncane, ukusika uma ukucutshungulwa kobuso be-rebound kukhulu, cishe izikhathi ezi-2 ~ 3 zensimbi engagqwali, okuholela ekubambiseni okukhulu, ukunamathela, ukugqoka okunamathelayo endaweni yamathuluzi.