I-OEM Custom Grey Iron Casting

Incazelo Yomkhiqizo

I-iron empunga, noma insimbi empunga, iwuhlobo lwensimbi olusansimbi olune-graphic microstructure.Lolu hlobo lwensimbi empunga siyibiza ngenxa yombala ompunga wokuphuka.Ukuze i-graphite igcobe i-cut futhi ihlephule ama-chips, insimbi empunga iyingxube evamile ye-cast ngenxa yezindleko zayo eziphansi kanye nokusebenza kahle.Ngaphandle kwalokho, ngenxa yokuthi i-graphite flakes i-self-lubricate, iphinde ibe ne-galling enhle futhi imelane nokugqoka.

Insimbi empunga iphinde ibe nokushwabana okuncane kokuqina kunezinye izinsimbi ezisansimbi ngenxa ye-graphite microstructure.I-Whecasting, i-elementi ye-silicon ingakhuthaza ukumelana nokugqwala okuhle futhi ikhulise uketshezi lapho isakaza.Insimbi empunga ngokuvamile ibhekwa njengelula ukuyishisela.Uma kuqhathaniswa nezinyeizinsimbi, insimbi empunga inamandla aphansi okudonsa kanye ne-ductility;yingakho umthelela kanye nokumelana nokushaqeka kwalolu hlobo lwezinto cishe akukho.

Amabanga Ensimbi Empunga Asetshenziswa Kaningi

| Insimbi Empunga | Ubukhulu bodonga/mm | C | Si | Mn | P≤ | S≤ |

| I-HT150 | <30 | 3.3-3.5 | 2.0-2.4 | 0.5-0.8 | 0.2 | 0.12 |

| 30-50 | 3.2-3.5 | 1.9-2.3 | 0.5-0.8 | 0.2 | 0.12 | |

| >50 | 3.2-3.5 | 1.8-2.2 | 0.6-0.9 | 0.2 | 0.12 | |

| I-HT200 | <30 | 3.2-3.5 | 1.6-2.0 | 0.7-0.9 | 0.15 | 0.12 |

| 30-50 | 3.1-3.4 | 1.5-1.8 | 0.8-1.0 | 0.15 | 0.12 | |

| >50 | 3.0-3.3 | 1.4-1.6 | 0.8-1.0 | 0.15 | 0.12 | |

| HT250 | <30 | 3.0-3.3 | 1.4-1.7 | 0.8-1.0 | 0.15 | 0.12 |

| 30-50 | 2.9-3.2 | 1.3-1.6 | 0.9-1.1 | 0.15 | 0.12 | |

| >50 | 2.8-3.1 | 1.2-1.5 | 1.0-1.2 | 0.15 | 0.12 |

Embonini yethu, singenza ukubunjwa kwensimbi empunga ngezinhlobo ezimbili ezingezansi:

Ukusakaza Kwegwebu Elilahlekile: Okuodwaukutshala imaliinqubo yezingxenye zensimbi ekhonjiwe, enezinzuzo eziningi zokukhiqiza ukufakwa kwemali okuncane kwensimbi empunga, njengezindleko zokukhunta ezigciniwe, ukunciphisa umjikelezo wokukhiqiza kanye nokwenza ngcono ukusebenza kahle kokukhiqiza.Ngenqubo elahlekile yokusakazwa kwegwebu, singasiza amakhasimende ethu ukuthi athole imikhiqizo enembayo ephezulu esezingeni eliphezulu, futhi kuzokwenziwa imisebenzi encane yokwenza imishini.

I-Resin Sand Casting: Inqubo eyinhloko yokukhipha isihlabathi yokulingisa okuncane nokuphakathi.Qhathanisa nezinye izinqubo zokuphonswa kwesihlabathi, ukukhishwa kwesihlabathi se-resin kuyindlela enembile kakhulu yokuphonsa eduze nokufaka utshalomali.Njengokuqina okuhle kwesihlabathi se-resin namandla aphezulu esikhunta sesihlabathi lapho sisakazwa kusenesikhathi, singase sikwazi ukuqeda ngempumelelo imbobo yokushwabana, ukukhubazeka kokuncipha kwensimbi empunga.

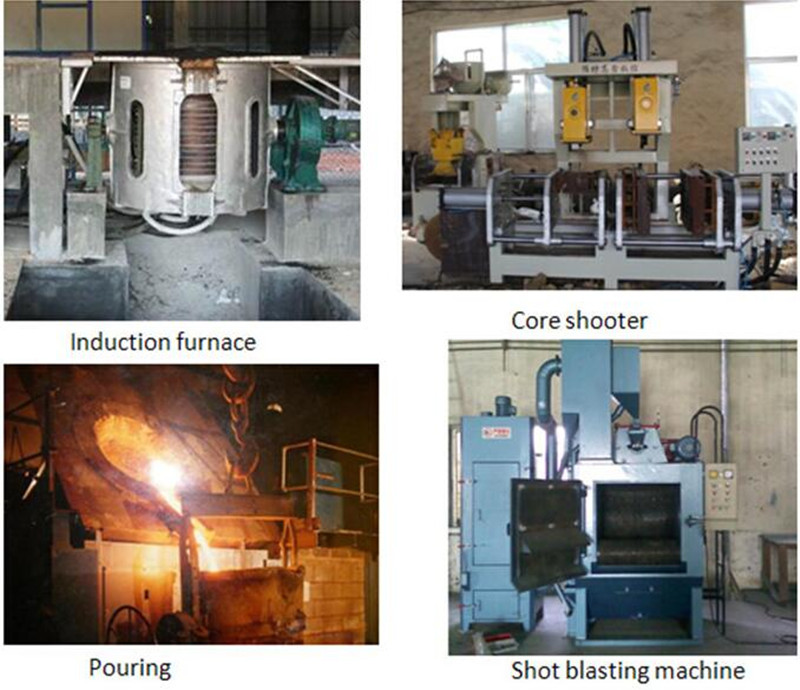

Imishini yokusakaza